Topline Glass & Glazing

Products

Address

Business Hours

Manufacturers of quality sealed units and glass products since 1977. Topline Glass and Glazing are Somerset’s largest sealed unit and glass supplier.

For all your glass and glazing requirements contact the team at Topline Glass and Glazing today.

Topline Glass & Glazing Ltd

The Conquest Business Park

Ilton, Ilminster

Somerset

TA19 9EA

All rights reserved © Web design by S.J.T.

Sealed Units

Topline Glass and Glazing Ltd are Somerset’s largest independent sealed unit manufacturer.

Quality Glass Products

We have been manufacturing insulated glass units since 1977, and as technology has advanced Topline has grown to accommodate the demand for higher specification units. With the space and facilities we have available, we are able to manufacture a huge range of unit types here at our premises with minimal lead times. Our purpose-built factory allows us to keep a vast range of stock, meaning we can turn around most units in less than a week.

All of our double and triple glazed units are made to order, meaning there are an endless number of options when it comes to shape, size and specification. Our new state-of-the-art automatic sealing robot allows us to efficiently clean, assemble, gas-fill and seal each individual unit to a consistently high standard every single time. In the last decade, the development and availability of glass products has improved significantly.

There are now a number of different glass types to suit a variety of applications and budgets. As technology has progressed, glass has become a multi-functional material that not only lets light through, but also provide thermal insulation, deflect UV rays, reduce noise levels, provide privacy and security, and even clean itself.

Standard Clear Glass

Transmits light at a high percentage but provides no sort of thermal or solar protection.

*Suitable for use in sheds/greenhouses and replacement sealed units.

Low-Emissivity Glass

Standard clear glass with a special coating on one side. The coated surface becomes the inner pane that faces into the cavity of an insulating glass unit (IGU). The low-emissivity coating absorbs the heat so that it does not travel across the air gap to the outer pane and the cooler outside air. Instead the coating reflects the heat back into the room.

*Suitable for use in all types of double and triple glazing. Now a standard for all new windows and doors fitted.

Low Iron Glass

An extra clear float glass with very high light transmission. It is practically colourless, with no green appearance at the edges. Ideal for use where glass edges are visible or where a neutral colour is desired. It also increases the solar gain when used in sealed units, and can improve the overall WER (Window Energy Rating).

*Suitable for use in single, double and triple glazing and for decorative purposes.

Solar-Control Glass

In hot climates, solar control glass can be used to minimise solar heat gain and help control glare. In colder climates, it can be used to balance solar control with high levels of natural light. Commonly used for glazed roofs.

*Suitable for use in double glazing and triple glazing, particularly glazed roofs.

Self-Cleaning Glass

Self-cleaning Glass uses the forces of nature to maintain a cleaner and clearer appearance. In a dual-action process organic dirt is broken down by daylight and is then washed away by rain, making it environmentally friendly and easy to maintain.

*Suitable for use in double glazing and triple glazing, particularly glazed roofs and hard to reach areas.

Anti-Sun Glass

Glass with a slight colour tint to reduce glare. Currently available in Grey, Bronze, Green and Blue.

*Suitable for use in double glazing and triple glazing.

Obscure Glass

Available in a variety of patterns and textures, including the standard Pilkington range (textured patterns), Satin (an all-over frosting), and the Pilkington Oriel Range (etched patterns)

*Suitable for single, double and triple glazing and for decorative purposes.

Glass Types

Other Products

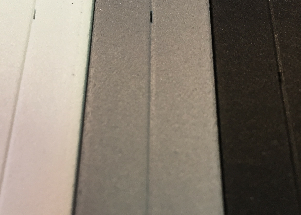

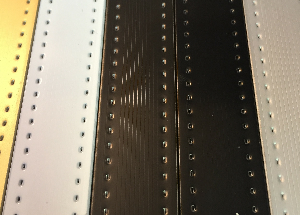

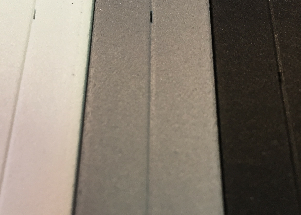

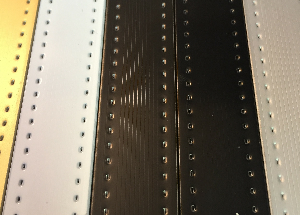

Spacer Bar Types

WARM-EDGE

Warm edge spacer bar insulates the edge of the unit where most heat is lost.

STEEL

Steel spacer is used in fire rated units. It’s resistance to heat keeps the glazing stable.

Aluminium spacer is lightweight and strong, but doesn’t provide insulation to the unit. ..

ALUMINIUM

Spacer bar is used between the panes of glass to create a cavity that provides thermal insulation. This cavity can be filled with air, or other gasses such as Argon to provide even better thermal insulation. The spacer bar itself is hollow, allowing it to hold desiccant that will absorb any moisture from within the sealed cavity. The bar is always assembled smaller than the glass, allowing sealant to be applied around the perimeter. Our spacer bars are cut to size using an automatic saw for millimetre precision, and connected using corner keys for a neat and secure finish.

Topline has one of the largest glass stocks in the country. We keep a wide variety of stock for a multitude of applications, meaning we can keep lead times to a minimum. Our automated glass cutting table keeps the process fast and efficient, with glass cut to precision every time.

Sealant Types

Dual Seal Method

Polyisobutylene (PIB), the primary seal, is applied to both edges of the spacer frame by use of a machine. This holds the two panes of glass together and provides the primary seal between the glass and the spacer frame, whilst sealing the cavity from the external atmosphere.

For the secondary seal we use Hotmelt. This single component compound is a thermoplastic material, meaning it will flow when hot and be solid when cool. Hotmelt is applied to the units at 170-190°C and cools very quickly creating a secure bond to the glass with minimal curing times.

Silicone Seal Method

Silicone sealant is used to seal structural units, generally found in commercial buildings, frameless or green oak glazing. It specifically needs to be used in applications that leaves the unit’s outer edge exposed to the daylight as it is UV resistant. Most other standard sealants will break down if exposed to UV and will result in failure of the unit. Silicone sealant does require time to cool down to its solid state, usually taking approximately 5 days to fully cure before the units can be transported and installed.

Find out more about structural units…

COLOURS:

Silver, White, Black, Bronze, Gold

SIZES:

4, 6, 8, 10, 12, 14, 16, 18, & 20mm

COLOURS:

Black, Grey, White

SIZES:

6, 8, 10, 12, 14, 16, 18, 20, 22, & 24mm

COLOURS:

Silver

SIZES:

6, 8, 10, 12, 14, 16, 18, & 20mm